-

By magnet

-

December 5, 2025

- 0 Comment

Samarium Cobalt Magnets: The Stable and Reliable Core Power of Modern Motors

In modern industrial drive systems, the performance of motors directly determines the efficiency and reliability of equipment. As the “heart” of the motor, samarium cobalt magnets, with their excellent magnetic performance and stability, have become an indispensable core component of motors. This permanent magnet material, made from rare earth element samarium and transition metal cobalt in precise proportions, provides continuous and stable power output for motors in aerospace, defense, industrial manufacturing, and other fields. This article will analyze how samarium cobalt magnets become the core power of motors from aspects such as material essence, performance characteristics, motor adaptation principles, application cases, and quality assurance.

1. Composition of Samarium Cobalt Magnets

The core competitiveness of samarium cobalt magnets comes from their unique composition and crystal structure, which form the foundation for providing stable power to motors. As an important branch of rare earth permanent magnet materials, its composition and structure determine its adaptability and reliability in the motor operating environment.

1.1 Precise Composition Proportions

Samarium cobalt magnets are mainly divided into two types: 1:5 type (SmCo₅) and 2:17 type (Sm₂Co₁₇). Their composition structure directly affects the motor’s performance:

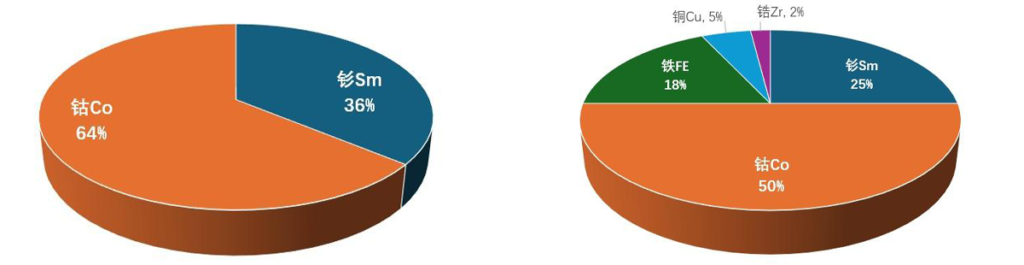

– 1:5 Type Samarium Cobalt: Composed of 1 samarium atom and 5 cobalt atoms, samarium accounts for about 35%, and cobalt accounts for about 65%. The higher cobalt content gives it excellent coercivity, allowing it to maintain stable magnetism in the strong reverse magnetic field during motor start-up and braking, preventing power decay caused by magnetic field fluctuations.

– 2:17 Type Samarium Cobalt: Composed of 2 samarium atoms and 17 cobalt atoms, elements like iron, copper, and zirconium are introduced in production to form the Sm₂(Co,Fe,Cu,Zr)₁₇ alloy. The cobalt content drops to 45%-60%, and iron accounts for 5%-25%. Through the synergistic effect of these elements, it significantly improves the magnetic energy product while maintaining high-temperature stability, meeting the power demands of high-power density motors.

This precise elemental ratio is not simply a mixture but achieved by adjusting atomic interactions, enabling the material to possess strong magnetism and adapt to the complex environment of motor operation, such as temperature and vibration.

1.2 Stable and Ordered Crystal Structure

The crystal structure of samarium cobalt magnets serves as the “physical skeleton” for their magnetic performance, with the structural characteristics of the two types ensuring stable motor operation:

– 1:5 Type Hexagonal Crystal Structure: Belonging to the CaCu₅-type hexagonal structure (space group P6/mmm), samarium atoms are located at the apex and center of the crystal, forming a tight layered arrangement, with cobalt atoms filling the gaps. This structure has a high atomic packing density and strong magnetic anisotropy along the c-axis. In motor magnetic field orientation design, the crystal c-axis can be aligned with the motor’s magnetic field to maximize magnetic field strength and improve motor power output efficiency.

– 2:17 Type Rhombohedral Crystal Structure: Belonging to the Th₂Zn₁₇-type rhombohedral structure (space group R-3m), samarium atoms form two parallel planes, with cobalt and doping elements forming a complex polyhedral network between the layers. The large structural gaps allow for more elements to replace, and through adjusting atomic exchange interactions, the magnetic domain structure remains stable even in high-temperature environments. This is key to the long-term reliable operation of motors using 2:17 type samarium cobalt magnets under high-temperature conditions.

The stability of the crystal structure ensures that samarium cobalt magnets will not undergo lattice distortion under temperature rises and mechanical stress during continuous motor operation, thus maintaining stable magnetic performance output.

2. Performance Characteristics: Tailor-Made Hard-Core Metrics for Motors

Samarium cobalt magnets are the core power source of motors due to their series of performance parameters, which are highly matched with motor operational needs. These parameters fundamentally ensure the motor’s power output, operational stability, and service life.

2.1 Core Magnetic Properties: Driving Motor Efficiency

– Residual Magnetic Induction (Br): The Br value of samarium cobalt magnets ranges from 0.5-1.2T (1:5 type 0.5-1.0T, 2:17 type 1.0-1.2T). In motors, this parameter directly determines the strength of the air-gap magnetic field. The higher the Br value, the greater the motor’s electromagnetic torque and power output. Compared to ferrite magnets (0.2-0.5T), samarium cobalt magnets provide multiple times the power for the same volume, enabling motor miniaturization and high power density designs.

– Intrinsic Coercivity (Hcj): 1:5 type samarium cobalt has an Hcj of over 15kOe, while 2:17 type ranges from 10-40kOe, much higher than the coercivity of neodymium-iron-boron magnets at high temperatures. This property allows the motor to resist interference from reverse magnetic fields during start-up, braking, and load fluctuations, ensuring stable power output. For example, in servo motors, high Hcj samarium cobalt magnets ensure precise speed and position control even during high-frequency forward and reverse rotations.

– Maximum Magnetic Energy Product (BH)max: 2:17 type samarium cobalt has an (BH)max of 16-35MGOe, while 1:5 type is 15-24MGOe. This parameter reflects the ability of the magnet to store and release magnetic energy and directly impacts energy conversion efficiency in motors. A higher (BH)max means the motor can output more mechanical energy with the same input power, reducing energy loss and improving operational efficiency.

2.2 Temperature Stability: Meeting Motor Heat Challenges

Motors generate a lot of heat during continuous operation, causing internal temperature rises that pose a severe challenge to the stability of the magnet’s magnetic properties. Samarium cobalt magnets’ temperature characteristics perfectly address this challenge:

– Curie Temperature (Tc): 1:5 type samarium cobalt has a Tc of about 750°C, and 2:17 type reaches 820°C, much higher than neodymium-iron-boron (230°C for standard types) and ferrite (100-200°C). The Curie temperature is the critical temperature at which a material loses its ferromagnetic properties. The higher the Tc, the more stable the magnet’s performance in the normal temperature range of motor operation (usually below 300°C), providing continuous and stable power.

– Temperature Coefficients: The temperature coefficient for samarium cobalt magnets’ residual magnetization (αBr) is -0.03%/-0.04%/°C, and the intrinsic coercivity temperature coefficient (αHcj) is -0.3%/°C for 1:5 type and about -0.2%/°C for 2:17 type. This means that during temperature fluctuations in the motor, the changes in magnetic performance are minimal. For example, when the motor temperature rises from 25°C to 200°C, the residual magnetization of 2:17 type samarium cobalt only drops by about 5.0%, while standard neodymium-iron-boron may decrease by 17.0%, ensuring consistent performance in different operating conditions.

2.3 Physical and Mechanical Properties: Adapting to the Motor Operating Environment

– Density and Hardness: Samarium cobalt magnets have a density of 8.3-8.5g/cm³ and a Vickers hardness (HV) of 500-600. The high density and hardness enable the magnets to withstand centrifugal force and mechanical vibration during high-speed motor operation without deforming or fracturing, thereby extending the motor’s lifespan.

– Electrical Resistivity and Corrosion Resistance: With a resistivity of about 70-120μΩ·cm, higher than metallic materials, this reduces eddy current losses and additional heating during motor operation. Its excellent corrosion resistance allows it to be used in humid, dusty motor environments without the need for additional coating, reducing maintenance costs.

3. Motor Integration: From Power Output to System Optimization

The application of samarium cobalt magnets in motors is not a simple component swap; rather, through deep integration with motor structures, they deliver comprehensive improvements in power performance, operational stability, and system efficiency. Their role in motors spans energy conversion, structural design, and system optimization.

3.1 Improving Energy Conversion Efficiency

In the energy conversion process of a motor, the high maximum energy product and low-loss characteristics of samarium cobalt magnets play a key role. Motors convert electrical energy into mechanical energy through the interaction of magnetic fields and current. The strong and stable magnetic field produced by samarium cobalt magnets reduces the excitation current and copper losses; meanwhile, their high resistivity lowers eddy-current losses, allowing more electrical energy to become useful mechanical energy. In aerospace propulsion motors, adopting samarium cobalt magnets can raise energy conversion efficiency by 15%–20%, significantly reducing the energy consumption of spacecraft.

3.2 Optimizing Motor Structural Design

The high magnetic performance of samarium cobalt magnets enables higher power output within a smaller motor volume, driving motor miniaturization and lightweighting. For example, in precision motors for medical devices, using samarium cobalt magnets can reduce motor volume by more than 30% and weight by 25%, saving device space and improving portability. In addition, thanks to their magnetic anisotropy, appropriate magnetic orientation design yields a more uniform magnetic field distribution, reducing vibration and noise during operation and enhancing user comfort.

3.3 Enhancing System Operational Reliability

System reliability depends on the long-term stability of each component. The high coercivity and environmental resistance of samarium cobalt magnets safeguard overall reliability. In drive motors for oil drilling equipment—where temperatures are high, vibration is severe, and corrosive media are present—samarium cobalt magnets’ stable magnetic properties and corrosion resistance ensure the motor will not fail over time due to magnet degradation, thereby reducing failure rates and maintenance costs. Their strong anti-interference capability also helps resist external strong magnetic fields, ensuring normal operation in complex electromagnetic environments.

4. Application Scenarios: The Go-To Choice for High-End Motors

With advantages in high-temperature endurance, vibration tolerance, and reliability, samarium cobalt magnets are widely used in various high-end motors, serving as the core power source in these fields.

– Satellite Attitude Control Motors: Satellites must adjust their attitude to keep solar panels pointed at the sun and antennas pointed toward Earth. Motors made with samarium cobalt magnets maintain stable magnetic performance amid extreme temperature swings from −196°C to 100°C, ensuring precise control.

– Space Shuttle Hydraulic Pump Motors: The hydraulic system of a space shuttle operates near the engines in high-temperature environments (around 250°C). Motors using samarium cobalt magnets can run efficiently under such conditions and provide stable power for the hydraulic system. Their coating-free design avoids outgassing in vacuum that could contaminate satellite optical instruments, safeguarding mission safety.

4.2 Defense

– Radar Antenna Drive Motors: Radar antennas rotate at high frequency to scan targets comprehensively; motor performance directly affects detection accuracy and response speed. Samarium cobalt magnet motors exhibit minimal magnetic performance changes between −40°C and 80°C, ensuring pointing accuracy (error < 0.01°). Their salt-spray corrosion resistance also enables long-term reliable operation in shipborne and airborne harsh environments.

– Nuclear Submarine Propulsion Motors: In deep-sea operation, propulsion motors must work under high temperature (above 150°C), strong vibration, and strong electromagnetic interference. With high coercivity and low eddy-current losses, samarium cobalt magnet motors resist external interference, maintain efficient and stable power output, reduce operational noise, and improve submarine stealth.

4.3 Advanced Manufacturing

– Semiconductor Wafer Transfer Motors: Wafer handling in semiconductor manufacturing demands extreme precision and stability. Motors with samarium cobalt magnets achieve ±0.001 mm positioning accuracy, meeting sub-7 nm process requirements. Stable magnetic performance ensures long-term operation without degradation that would otherwise affect transfer accuracy, improving fab yield.

– High-Precision CNC Machine Servo Motors: Machining accuracy in CNC tools depends on servo motor positioning precision and response speed. Leveraging their high maximum energy product and low temperature coefficients, samarium cobalt magnet motors maintain stable power at high speeds to deliver micrometer-level positioning. When machining precision molds, CNC machines using samarium cobalt magnet motors can control machining error within 0.002 mm, significantly improving product quality.

4.4 Energy & Chemical

– High-Temperature Magnetic Pump Motors: In petrochemical production, high-temperature magnetic pumps convey hot, high-pressure, and corrosive media. Their drive motors must operate at 250–300°C. Motors with samarium cobalt magnets maintain stable magnetic performance under these conditions, providing continuous power and ensuring safe media transport. Compared with traditional motors, service life is extended by more than 5×, reducing maintenance costs.

– Geothermal Power Drive Motors: During geothermal power generation, drive motors work at 200–250°C. Thanks to high-temperature resistance, samarium cobalt magnet motors can be placed directly downhole, eliminating long drive shafts and cutting transmission losses, thereby increasing power generation efficiency by 15%–20%.

5. Quality Assurance: Performance Commitments Under Rigorous Standards

As a core component of motors, the quality of samarium cobalt magnets directly affects motor performance and reliability. To ensure product quality, CJL follows strict standards and specifications from raw material procurement through processing to final testing, ensuring every magnet meets high-end motor requirements.

5.1 Strict Raw Material Control

Purity of raw materials underpins performance. High requirements are placed on the purity of samarium, cobalt, and other dopants. Samarium purity must reach ≥99.9% (3N) with oxygen ≤500 ppm; cobalt purity must reach ≥99.5% (2.5N) with sulfur <100 ppm. By using combined “solvent extraction + vacuum distillation” to refine samarium and electrolytic refining for cobalt, impurity levels are minimized to provide high-quality feedstock for downstream production.

5.2 Precision Manufacturing Process

Samarium cobalt magnets are produced by powder metallurgy. Every step—from alloy melting to sintering and aging—is tightly controlled:

– Alloy Melting: Raw materials are mixed in precise ratios and melted at 1500–1600°C in a vacuum induction furnace. High-purity argon stirring ensures compositional uniformity, followed by rapid cooling to form ingots that avoid segregation.

– Powdering and Orientation: Ingots are crushed and jet-milled to 3–5 μm powders. A strong magnetic field (1.5–2.0 T) orients particle c-axes in parallel before pressing into green compacts, ensuring density and alignment.

– Sintering and Aging: Green compacts are vacuum-sintered at 1100–1250°C to form dense crystal structures. 2:17 samarium cobalt additionally undergoes aging (hold at 850–900°C, then slow cool to 450–500°C) to optimize precipitate distribution and increase coercivity.

5.3 Comprehensive Testing System

A comprehensive test system ensures performance compliance:

– Magnetic Performance Testing: Using permanent magnet characterization systems, residual magnetization (Br), coercivity (Hcb, Hcj), and maximum energy product ((BH)max) are measured at room temperature and elevated temperatures (e.g., 200°C, 300°C) to confirm specifications.

– Physical Property Testing: Density and hardness are measured with densimeters and hardness testers; dimensional accuracy is checked with laser micrometers and CMMs to ensure conformance to design.

– Reliability Testing: Environmental tests such as high/low temperature cycling, vibration, and shock simulate motor conditions to verify stability under harsh environments. For example, after cycling between −196°C and 300°C, magnetic performance decay must be controlled within 5% to guarantee long-term reliability in service.

6. Continuous Innovation for Performance Breakthroughs

As industrial technology advances, motors face ever-higher performance requirements. Samarium cobalt magnets continue to evolve to meet new application demands. CJL will invest in R&D to enhance scalability in the following directions:

– Higher Performance: Optimize composition design and process parameters to further increase maximum energy product and coercivity, enabling even higher power output in smaller motors.

– Lower Cost: Explore new dopants and manufacturing processes to reduce cobalt usage and production costs.

– Functional Composites: Combine samarium cobalt magnets with other functional materials to add properties such as thermal or electrical conductivity, aligning with the trends toward integration and multifunctionality in motor systems.

Samarium cobalt magnets, as a motor’s core power source, set a professional benchmark in high-end motors with excellent magnetic performance, stable temperature characteristics, and reliable operation. From the extreme environments of aerospace to the precision control of advanced manufacturing, they consistently provide stable and reliable power, driving continuous progress in industrial technology. Looking ahead, with sustained innovation, samarium cobalt magnets will deliver higher performance at lower cost, injecting new vitality into the motor industry and becoming the core choice for more high-end motors.

CJL. is an explorer and practitioner in the field of samarium cobalt. The company focuses on the R&D, production, and application of high-end permanent magnetic materials such as samarium cobalt magnets. With deep understanding of material characteristics and exquisite manufacturing processes, it provides high-performance, highly reliable samarium cobalt magnet products for various industries. Whether it’s the extreme demands of aerospace or the precision control needs of advanced manufacturing, Hangzhou CJL leverages a professional technical team and a complete quality assurance system to deliver customized solutions—helping permanent-magnet motors achieve continuous development and breakthroughs in high-end fields.